Analytical technologies

on

Skin care

peer-reviewed

Microplastics in cosmetic and detergent products: recent regulation and analytical test

ALESSIA APREA*, DAVIDE MARIANI, ESTER TRIMIGNO, ROMINA CORTELLA

*Corresponding author

Innovhub-SSI, Milano, Italy

ABSTRACT: The recent regulation (1) regarding the intentionally added microplastics content and the attention for the unintentional microplastics release are very interesting and central topic nowadays. The regulation has a significant impact on cosmetic and detergent products, in terms of ban on use of microparticles, albeit with a delay in implementation times. This article wants to give a brief summary of the “state of the art” regarding these topics, highlighting some crucial points of the Regulation and suggesting some analytical method to detect microplastics in cosmetic and detergent products, suitable for quality controls about the presence of these pollutants in raw materials or commercial products.

Introduction

Microplastics have received great attention in the last years all over the world. This increasing interest is mainly due to their potential harmful effects on the biota and humans through the food chain or from contact with contaminated products (2, 3). Furthermore, the negative interactions are also extended to all contaminants (chemical and biological) of which microplastics can be carriers (4, 5, 6), so microplastics could be also infections or toxic chemicals vectors. It was recently estimated that 8 M tons per year of plastics are entering the marine environment, due to accidentally or deliberately dumped litter (7). The awfulness of this situation is due to the non-biodegradability of plastics items that are accumulating in the environment as fragments of decreasing size (microplastics) (7).

Microplastics show a relevant heterogeneity, in terms of chemical classification (type of polymer), size and shape, deriving from several kind of thermal and/or mechanical degradation from macroscopic plastic items (secondary microplastics), furthermore microplastics are contained as intentionally added microparticles for specific functional purposes (primary microplastics) in several kinds of products (4). According to ECHA (2019), microplastics are defined as: "particles containing solid polymers, to which additives or other substances may have been added, with dimensions between 1 nm ≤ x ≤ 5 mm (particles) or fibres with a length between 3 nm ≤ x ≤ 15 mm, with a length/diameter ratio >3”. Biodegradable polymers, polymers with water solubility > 2g/l and natural polymers (not modified except by hydrolysis) are excluded from this definition (8). An extensive definition and description of microplastics is necessary to fully understand their distribution patterns in the environment and also to allow the development of reliable and robust analytical protocols (9), therefore an appropriate description of all the characteristics of microplastics, such as size, chemical nature, colour and shape, is very relevant and useful for understanding the origin and way of distribution in the environment of these contaminants (10).

As previously mentioned, primary microplastics are those that are intentionally added to other products with a specific functional activity, for example exfoliating particles in scrubs or in detergents, opacifiers in cosmetics in cosmetics (4, 11) or glitter in make-up and nail products. Many countries are addressing the primary microplastics problem by introducing national laws to ban or restrict the intentional addition of functional microplastics into various types of products (12), see some examples in the table below (Table 1):

Table 1. (12) National laws to ban or restrict the intentional addition of functional microplastics.

Recently (October 2023) has been published the European Commission Regulation that insert microplastics in the XVII Allegate of REACH (Commission Regulation (EU) 2023/2055) ( ). In this context, great attention is focused on cosmetics and detergents samples, for which the ban regarding to the intentionally added microbeads is already in force and within a few years will be ban also the intentional addition of microparticles in general, firstly in rinse-off products and then also in the live-on (Commission Regulation (EU) 2023/2055)(13).

Furthermore European Commission has published a Proposal for a Regulation of the European Parliament and of the Council on preventing plastic pellet losses to reduce microplastics pollution (14).

Figure 1. Skin Section with Microbiome. Most microorganisms live in the superficial layers of the stratum corneum and in the upper parts of the hair follicles. Some reside in the deeper areas of the hair follicles and are beyond the reach of ordinary disinfection procedures. There bacteria are a reservoir for recolonization after the surface bacteria are removed.

Materials and methods

Studies of major depressive disorder have been correlated with reduced Lactobacillus and Bifidobacteria and symptom severity has been correlated to changes in Firmicutes, Actinobacteria, and Bacteriodes. Gut microbiota that contain more butyrate producers have been correlated with improved quality of life (1).

A study in healthy women providing probiotic yogurt for four weeks showed an improvement in emotional responses as measured by brain scans (2). A subsequent study by Mohammadi et al. (3) investigated the impacts of probiotic yogurt and probiotic capsules over 6 weeks and found a significant improvement in depression-anxiety-stress scores in subjects taking the specific strains of probiotics contained in the yogurt or capsules. Other studies with probiotics have indicated improvements in depression scores, anxiety, postpartum depression and mood rating in an elderly population (4-7).

Other studies have indicated a benefit of probiotic supplementation in alleviating symptoms of stress. In particular, researchers have looked at stress in students as they prepared for exams, while also evaluating other health indicators such as flu and cold symptoms (1). In healthy people, there is an indication that probiotic supplementation may help to maintain memory function under conditions of acute stress.

About the Commission Regulation (EU) 2023/2055

From 17 October 2023 is in force the Commission Regulation (EU) 2023/2055 restricting synthetic polymer microparticles on their own or intentionally added to mixtures.

Concerning cosmetics and detergents products, the paragraph 6 defines the transition periods during which the ban on the placing on the market of microplastics intentionally added to these products will be applied, except that the ban is already active for microbeads/microspheres. In particular:

- From 17 October 2027 – Rinse off products

- From 17 October 2029 – Leave on products

- From 17 October 2029 – Encapsulation of fragrances

- From 17 October 2035 – Lip products, nail products and make-up products, unless such products containing microbeads*

*From 17 October 2031 to 16 October 2035, suppliers of products referred to in paragraph 6 point (c) containing synthetic polymer microparticles shall provide a label on the product indicating: “This product contains microplastics”.

However, the restriction is not applied to “synthetic polymer microparticles which are contained by technical means so that releases to the environment are prevented when used in accordance with the instructions for use during the intended end use; synthetic polymer microparticles the physical properties of which are permanently modified during intended end use in such a way that the polymer no longer falls within the scope of this entry; synthetic polymer microparticles which are permanently incorporated into a solid matrix during intended end use” (paragraph 5 – Commission Regulation 2023/2055).

Detection method of microplastics in cosmetics and detergents products

Nowadays there isn’t a unique analytical method to detect microplastics because of the wide extension of their dimensional range (0,1 nm – 5 mm) and also because of the different type of sample matrices in which microplastics can be found. For these purposes, Innovhub SSI developed an analytical method to detect microplastics in moisturizing cream samples and this method is scalable to detergents products.

The developed method for the determination of microbeads and microparticles in cream based cosmetics and detergents samples includes both gravimetric evaluation and quali-quantitative analysis of the particles by micro-FTIR. It provides a preliminary extraction procedure, involving the use of an automatic solid phase extractor (ASE 350), equipped with stainless steel extraction cells. Through the extraction process it is possible to remove the components of the cosmetic/detergent formulation and obtain the purified microplastics eventually present in the sample. The analytical method was defined for a theoretical low concentration limit of 0.025 % (w/w) four times lower the European Regulation limits. Known amounts of standard coloured (red of 355-425 µm size and blue of 106-125 µm size) microbeads were mixed in a defined quantity of cream, in order to have the desired microplastics concentration for sample. Working parameters were optimised for maximum microplastics recovery without damaging them. In order to evaluate also microplastics unintentional release from container fragmentation, samples containing microplastics obtained by trituration of PE-PP caps (average size of 180-250 µm) have been analysed.

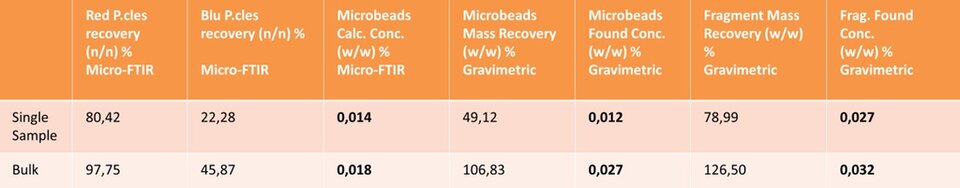

In Table 2 were summarized the average values obtained from the experimental procedures, in particular for the single aliquot sample and for bulk sample. It can be observed that the bulk sample concentration results are very closed to the real concentration.

Table 2. Recovery percentages and found concentrations (mean values).

Taking into account both gravimetric and FTIR analysis allows us to report more confident results. The importance of having such a validated and performing procedure is principally due to the necessity to have a strong instrument to be employed for regulatory and quality controls or for solving eventually occurring disputes on the presence of this pollutant in raw materials or commercial products.

Conclusion

In light of what has been described, it is clear that the problem of microplastics is now increasingly relevant and subject to great attention. In addition to finding new technological solutions to eliminate the use of microparticles, it is important to have analytical tools capable of identifying and quantifying them, not only for regulatory purposes, but also to evaluate the new technological solutions.

In this article we offered an informative point on the topic, underlining that an analytical method has been developed in the Innovhub laboratories which allows the possible content of microplastics in cosmetic or detergent samples to be characterized and quantified in concentrations up to four times lower than the limit imposed from the European Regulation.

Acknowledgements

The method was developed thanks to the funds dedicated to Institutional Projects of Innovhub-SSI.

References and notes

- REACH (2023) Commission Regulation (EU) 2023/2055, amending Annex XVII to Regulation (EC) No 1907/2006 of the European Parliament and of the Council concerning the Registration, Evaluation, Authorisation and Restriction of Chemicals (REACH) as regards synthetic polymer microparticles. https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32023R2055

- Aparna Kuna and M Sreedhar (2019) Microplastics in food chain. Health Action, 27-28

- Saidu M. Bashir et al (2021) Personal Care and Cosmetic Products as a Potential Source of Environmental Contamination by Microplastics in a Densely Populated Asian City. Frontiers in Marine Science, 8, https://doi.org/10.3389/fmars.2021.683482

- Boucher and Friot (2017) Primary Microplastics in the Oceans: A Global Evaluation of Sources. IUCN report, https://doi.org/10.2305/IUCN.CH.2017.01.en

- Dunzhu Li et al (2020) Microplastic release from the degradation of polypropylene feeding bottles during infant formula preparation. Nature Food, 1, 746-754. https://doi.org/10.1038/s43016-020-00171-y

- Wenfeng Wang and Jun Wang (2018) Investigation of microplastics in aquatic environments: An overview of the methods used, from field sampling to laboratory analysis. Trends in Analytical Chemistry, 108, 195-202. https://doi.org/10.1016/j.trac.2018.08.026

- S. Primpke et al. (2017) An automated approach for microplastics analysis using focal plane array (FPA) FTIR microscopy and image analysis. Anal. Methods, 9, 1499–1511

- ECHA (European Chemical Agency) (2019), ANNEX XV Restriction report-Proposal for a restriction, version number 1.2., Helsinki

- Wenfeng Wang and Jun Wang (2018) Investigation of microplastics in aquatic environments: An overview of the methods used, from field sampling to laboratory analysis. Trends in Analytical Chemistry, 108, 195-202. https://doi.org/10.1016/j.trac.2018.08.026

- World Health Organization (2019) Microplastics in drinking-water, ISBN 978-92-4-151619-8

- Bank (2022) Microplastic in the Environment: Pattern and Process. Springer Link, https://doi.org/10.1007/978-3-030-78627-4

- Yingying Li (2022) Legislation and Policy on Pollution Prevention and the Control of Marine Microplastics. Water 14, 2790-2804. https://doi.org/10.3390/w14182790

- https://eur-lex.europa.eu/eli/reg/2023/2055/oj

- https://eur-lex.europa.eu/legal-content/EN/HIS/?uri=COM%3A2023%3A645%3AFIN