Packaging

Skin care

KEYWORDS

peer-reviewed

The circular beauty of wood

Denisa Stircea

Senior Category Specialist, Quadpack, Spain

ABSTRACT: Cosmetics packaging is a major contributor to global waste, with most of it discarded after use. While recycling is often promoted, true circularity begins with reuse and waste reduction. Packaging materials like plastics are more persistent in the environment and pose great pollution risks. This article explores how wood offers a premium, renewable alternative to plastic – one that adds a warm, sensory quality to the user experience. With wood, change does not have to be radical.Wood can replace plastic or other materials without disrupting the look and feel of the brand’s design. When sourced from managed forests and processed cleanly, it becomes a big step in a beauty brand’s sustainable journey. Wooden components can be created along eco-design principles, before biodegrading in the soil as part of its biological loop. With creative flexibility added to the mix, wood presents a compelling solution for circular beauty packaging.

??????????????????

“

“A study in healthy women providing probiotic yogurt for four weeks showed an improvement in emotional responses as measured by brain scans”

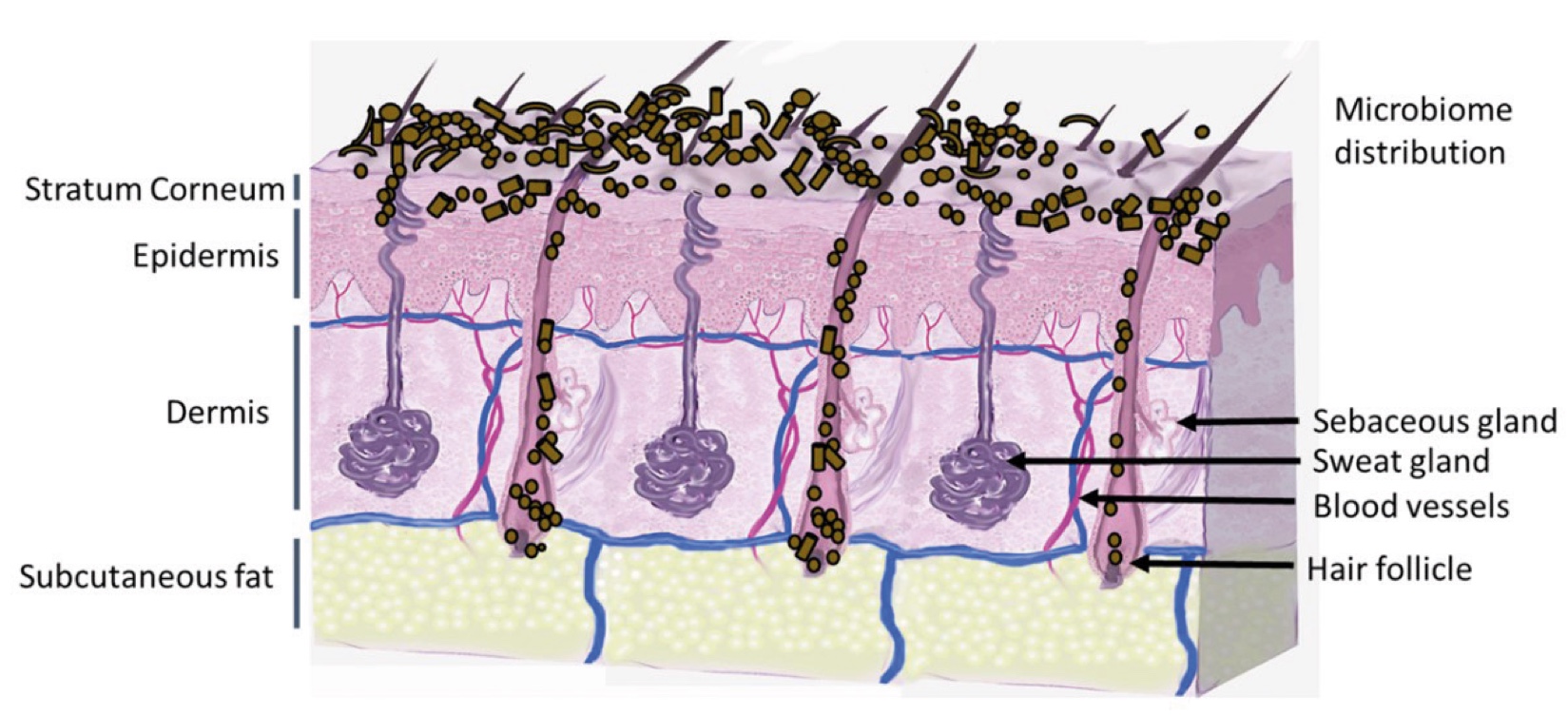

Figure 1. Skin Section with Microbiome. Most microorganisms live in the superficial layers of the stratum corneum and in the upper parts of the hair follicles. Some reside in the deeper areas of the hair follicles and are beyond the reach of ordinary disinfection procedures. There bacteria are a reservoir for recolonization after the surface bacteria are removed.

Materials and methods

Studies of major depressive disorder have been correlated with reduced Lactobacillus and Bifidobacteria and symptom severity has been correlated to changes in Firmicutes, Actinobacteria, and Bacteriodes. Gut microbiota that contain more butyrate producers have been correlated with improved quality of life (1).

A study in healthy women providing probiotic yogurt for four weeks showed an improvement in emotional responses as measured by brain scans (2). A subsequent study by Mohammadi et al. (3) investigated the impacts of probiotic yogurt and probiotic capsules over 6 weeks and found a significant improvement in depression-anxiety-stress scores in subjects taking the specific strains of probiotics contained in the yogurt or capsules. Other studies with probiotics have indicated improvements in depression scores, anxiety, postpartum depression and mood rating in an elderly population (4-7).

Other studies have indicated a benefit of probiotic supplementation in alleviating symptoms of stress. In particular, researchers have looked at stress in students as they prepared for exams, while also evaluating other health indicators such as flu and cold symptoms (1). In healthy people, there is an indication that probiotic supplementation may help to maintain memory function under conditions of acute stress.

Lessons from History: Perfume as a Sacred Connector

Packaging accounts for much of the world’s waste and part of that comes from cosmetics. According to the British Beauty Council, 95% of cosmetic packaging is thrown away, making it one of the biggest sustainability challenges facing the beauty industry (1). Growing consciousness, consumer pressure and new legislation are pushing brands to rethink their packaging to reduce environmental impact. While recycling can generally be considered a good thing, the Ellen Macarthur Foundation points out that it should be a last resort, as the embedded value in products and components are lost. It also recognises that “it is vitally important as the final step that allows materials to stay in the economy and not end up as waste” (2).

In fact, the proposed EU Packaging and Packaging Waste Regulation (PPWR) looks to avoid waste in the first place, with binding targets for waste reduction, as well as recyclability. Instead, prevention is the priority. When it comes to beauty packaging, the goal is to reuse, reduce and recycle – in that order. So how can it best be achieved? One possible answer comes from nature itself: wood.

A natural solution

Wood as a packaging material offers a premium and sustainable alternative to plastics and other standard options. When sourced from sustainably-managed forests, it becomes an endlessly renewable resource. Far from killing trees, these forests are husbanded for long-term health, preserving biodiversity, protecting soil and water and ensuring a continuous supply. Moreover, they act as a carbon sink. In this respect, young forests are more effective than old forests, absorbing more CO2 from the atmosphere. Programmes like the Forest Stewardship Council (FSC) (3) and the Programme for the Endorsement of Forest Certification (PEFC) (4) offer a complete chain of custody from the forest to the final product, with complete transparency. On a human level, both foster family and community forests for collective impact, while it is also worth noting that the process of extraction is non-toxic.

In short, wood is a renewable, natural and safe material, but its characteristics make it particularly suited to beauty packaging. Besides adding a sensory dimension to a product, it is also a canvas for creativity. Wood can be converted into infinite geometric shapes, thanks to modern computer-numeric controlled (CNC) milling machines. A host of decoration techniques – from laser engraving to lacquering – can transform its aesthetics, highlighting the material’s natural origins or hiding it completely under an ultra-luxe finish. Its versatility makes it adaptable to any kind of brand image, making it suitable for mass market and prestige brands, and everyone in between.

There is a financial advantage to using wood, too. To start with, no moulds are required. CNC machines are simply programmed to produce a shape and wood-turning equipment creates cylindrical components like fragrance caps. This, in turn, allows faster prototyping and shortens overall development time. A reduced capital expenditure and a fast time to market combine to make wood economically viable for most brands.

Eco-design

When it comes to lowering the impact of beauty packaging, with wood, change does not have to be radical. Cosmetics companies can enhance sustainability – and maintain their brand image – simply by switching to a different material. Wooden packaging solutions, such as compacts, lipstick cases and fragrance caps, can be designed from the outset to be refillable, reusable and easily dismantlable after use. And with the right choice of wood essence, incredible looks can be achieved.

Dismantling becomes wholly unnecessary in the case of monomaterial components. Where wood previously lacked functionality, designs like Quadpack’s Woodacity closure systems allow the material to function like plastic. This eliminates the need for caps to have plastic inners. Instead, their interior structures allow them to snap, twist, push or click securely onto a bottle. Monomaterial design simplifies recycling, but wood lends itself perfectly for reuse or a second life, too. Think wooden jars as jewellery boxes or wooden caps as seedling markers. In a recent collaboration between Quadpack and Spain’s prestigious EADA business school (5), students proposed alternative end-of-life scenarios for its monomaterial wood closures, based on collection, reuse and seeding. It is this kind of out-of-the-box thinking that opens up a world of potential towards achieving circularity.

Sustainable transformation

Taking a step back, one of the environmental benefits of wood is clean manufacture. Transformation uses less water and energy, compared to packaging made of fossil fuel-based materials like polyolefins. Its conversion process is generally much cleaner than other standard packaging materials. No high temperatures are needed for treatment, nor are any chemicals or water required for production.

Wood is a renewable material in more ways than one. Production scrap can be collected and repurposed into secondary products like chipboard or animal bedding. Factories equipped with a biomass plant are able to process wood scrap to generate thermal energy. Quadpack Wood, for example, uses it to power its temperature control systems and wood-drying ovens. This practice not only minimises waste, but also lowers fossil fuel dependency.

On-site processing further shortens the carbon cycle through bypassing external waste treatment.

Of course, any wooden component needs to be finished with some kind of treatment. Decoration techniques like spray coating do have an environmental impact, as they produce volatile organic compounds. Here, too, however, the effects can be mitigated by emission control systems. Regenerative thermal oxidisers are designed to transform volatile organic compounds into harmless substances like water vapour (H20) and carbon dioxide (CO2).

A biological cycle

So wood is clean to harvest and transform, but the goal is circularity. A circular design looks to extend a pack’s use, by making it recyclable or reusable. Rather than disposal at the end of life, it looks to ‘close the loop’, by transforming the used pack into raw material. This technical cycle is applicable to plastics, some types of which can be chemically or mechanically recycled to make new packaging. Wood, on the other hand, has vastly different properties. When designed for circularity, it is subject to another kind of cycle – a biological loop.

The distinction between a technical and biological loop was popularised by the Ellen Macarthur Foundation’s butterfly diagram (6) – now a reference in the industry. On one side, we have synthetic materials, such as plastics. The technical loop involves processes to keep these products in circulation as long as possible. On the other side, we have biological materials such as wood or cork. The biological loop sees these biodegrade, safely decomposing in the soil and nourishing new growth. Wood does not require processes like recycling to biodegrade. However, packaging can still be engineered with features to make it suitable for reuse or alternative uses, extending its end of life. In this sense, wooden solutions can combine biological and technical loops in the same product.

At the end of the day

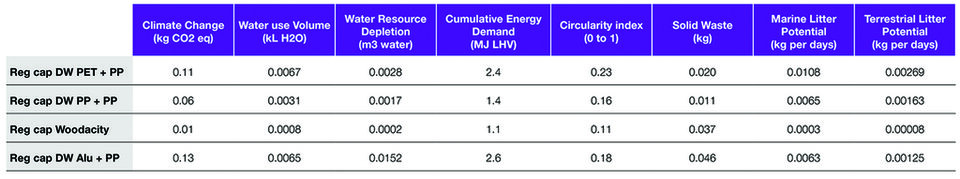

Wood’s sustainable properties are generally well-known, but there is still much confusion about its end of life. The lack of a domestic waste stream is a barrier to its uptake for many brands. After all, regulations tend to focus on the recycling of plastics, which are more persistent in the environment and pose greater pollution risks. In this case, recycling has a higher immediate environmental benefit. Nevertheless, the impact of wood is significantly lower than other packaging materials, even when incinerated or left to biodegrade in landfill. Eco-toxicity tests of varnished wooden caps at the ITENE Research Center in Spain have shown them to be safe and non-toxic (7) when left to degrade in soil. Life-cycle analyses have also proven that wooden caps compare favourably to plastic caps in terms of environmental impact (see Figure 1) (8).

Figure 1. LCA comparison of a monomaterial Woodacity® cap and others made with PET, PP and aluminium. Wood shows a lower impact in all metrics besides circularity and solid waste, as LCA tools currently do not factor in the biological loop and focus on domestic recycling, even though wood is mostly safe to discard or incinerate.

It is true that, for beauty packaging, wood is rarely used alone. Most often, it is combined with a bottle, a compact tray or a stick mechanism, but these, too, can be designed for circularity, though subject to a different loop.

Sustainability is a journey, after all. There are no instant, perfect solutions, but that should not stop anyone from moving in the right direction. Wood is an easy step in that journey, a powerful move towards circularity. This natural material has so much to offer, especially when manufacturers and brands continue to push its limits. Working together, such collaboration turns wood packaging into a premium, responsible and truly circular experience.

Conclusion

The future of cosmetics lies in the continued evolution of holistic approaches which represents a transformative shift in the industry, merging scientific advancements, natural ingredients, and wellness principles. By understanding and embracing the interconnectedness of these elements, the cosmetics industry can cultivate products that not only enhance external beauty but also contribute to the overall well-being of individuals and the planet.

The interplay between beauty from within and topical cosmetics is the key for future products. The integration of biotechnology and green chemistry is revolutionizing cosmetic formulations, offering sustainable and biocompatible alternatives.

Developers can implement blockchain to trace the journey of ingredients from source to product. Nevertheless, the efficacy of the natural products should be scientifically proven. Marketers can communicate transparency as a brand value, and parallelly educate consumers by highlighting how specific ingredients contribute to radiant and healthy skin.

By embracing the synergy between these approaches and leveraging scientific advancements, the cosmetics industry can provide consumers with comprehensive beauty solutions that cater to both internal and external dimensions of beauty.

Surfactant Applications

The application area lends itself particularly well to the use of AI. Active today in this area is the US company Potion AI (6). The company provides AI-powered formulation tools for beauty and personal care R&D. Their offerings include Potion GPT, next generation ingredient and formula databases and AI document processing. Potion’s work could have a significant impact on the entire surfactant value chain, from raw material suppliers to end consumers. By using their GPT technology, they can help target work toward novel surfactant molecules that have optimal properties for specific applications. By using their ingredient and formula databases, they can access and analyze a vast amount of data on surfactant performance, safety, and sustainability. By using their AI document processing, they can extract and organize relevant information from patents, scientific papers, and regulatory documents. These capabilities could enable Potion AI's customers to design and optimize surfactant formulations that are more effective, eco-friendly, and cost-efficient. A particularly interesting application for this type of capability is deformulation.

Deformulation is the process of reverse engineering a product's formulation by identifying and quantifying its ingredients. Deformulation can be used for various purposes, such as quality control, competitive analysis, patent infringement, or product improvement. However, deformulation can be challenging, time-consuming, and costly, as it requires sophisticated analytical techniques, expert knowledge, and access to large databases of ingredients and formulas.

AI can potentially enhance and simplify the deformulation process by using data-driven methods to infer the composition and structure of a product from its properties and performance. For example, AI can use machine learning to learn the relationships between ingredients and their effects on the product's characteristics, such as color, texture, fragrance, stability, or efficacy. AI can also use natural language processing to extract and analyze information from various sources, such as labels, patents, literature, or online reviews, to identify the possible ingredients and their concentrations in a product.

Figure 2. Skin Section with Microbiome. Most microorganisms live in the superficial layers of the stratum corneum and in the upper parts of the hair follicles. Some reside in the deeper areas of the hair follicles and are beyond the reach of ordinary disinfection procedures. There bacteria are a reservoir for recolonization after the surface bacteria are removed.

References and notes

- British Beauty Council. Planet Positive Beauty Guide - How to make greener beauty choices https://britishbeautycouncil.com/ppbg/packaging/

- Ellen MacArthur Foundation. Circulate Products and Materials. https://www.ellenmacarthurfoundation.org/circulate-products-and-materials

- Forest Stewardship Council International. Chain of custody certificationhttps://fsc.org/en/chain-of-custody

- Programme for the Endorsement of Forest Certification. Chain of Custody of Forest Based Products https://standards.pefc.org/the-standards/chain-of-custody

- Quadpack News. Circular thinking: graduate students analyse wood’s end of life https://www.quadpack.com/news/news/14349063/circular-thinking-graduate-students-analyse-woods-end-of-life/

- Ellen MacArthur Foundation. The butterfly diagram: visualising the circular economy. https://www.ellenmacarthurfoundation.org/circular-economy-diagram

- Eco-toxicity tests at ITENE Research Center, meeting the criteria set out in EN 13432-2001 annex E modifying OECD 208:2006.

- Life-cycle analysis comparison carried out using Piqet LCA tool, published in Quadpack’s 2021 white paper on Wood and Beauty Packaging